Sustainability

SustainabilityContribution to a Sustainable Global Environment

To realize a sustainable society, we recognize the impact of business activities on the underlying global environment and will sincerely address environmental challenges.

Realization of Decarbonized Society

LED lighting for warehouses

freezers upgrades

elimination of CFCs

(natural refrigerants, positive pressure systems)

We are working on initiatives to reduce environmental impact at our warehouses.

As part of our energy-saving measures, in addition to switching the lighting fixtures from fluorescent lights to LED, we are also implementing positive pressure systems in the loading bays (spaces where vehicles dock to load and unload goods) to prevent cold air from escaping in chilled and frozen warehouses, to reduce electricity consumption.

Additionally, we are working to reduce greenhouse gas emissions by upgrading to refrigerators with a lower global warming potential and installing refrigerators that use natural refrigerants at new offices.

We will continue our endeavors in introducing equipment with lower environmental impact.

Introduction of LED Lighting

Introduction of LED LightingShared delivery and container transportation

(transition to modal shift)

Before the company’s establishment in 1966, we operated as the warehousing division of Kewpie Corporation (hereinafter referred to as Kewpie), engaging in the joint delivery of Kewpie products and those of other companies in the same industry. Even today, we continue to excel in efficient and low-CO₂ cold-chain joint delivery services.

In 1982, we developed a dual-compartment freezer truck and began joint delivery services for two temperature zones, chilled and frozen. In 2010, we developed the flexible vehicle “FCD3+1”, which accommodates three temperature zones.

In 2015, we began railway transportation using 31-foot containers, promoting a modal shift to achieve transportation with lower CO₂ emissions.

In the future, as a leading food logistics company, we will continue to be innovative, take on new challenges, and fulfill our social responsibilities.

Vehicles at the time of establishment

Vehicles at the time of establishment Trailer transport using RORO ships and ferries

Trailer transport using RORO ships and ferriesIntroduction of EV trucks

K. Tis Corporation, which serves as the Group’s main transportation arm, introduced two EV trucks in 2022.

They are used for deliveries in the Kanto area, which can reduce CO₂ emissions by 15.3 tons per EV truck annually.

The engines have been replaced by motors, resulting in no vibrations or noise, and drivers have expressed positive feedback about the comfort.

EV truck

EV truckGeneration and use of renewable energy

We have installed solar power generation equipment at multiple offices, and the electricity generated is either for in-house consumption or sold to power companies.

○Self-Consumption Sales Office:

Nakai Center, Saijo Center

○Electric Power Sales office

Matsudo Center, Tokorozawa Logistics Center, Itami Third Center

>> K.R.S. Power Plants

Introduction of solar power generation systems

Introduction of solar power generation systemsPromotion of Resource Management and Resource Recycling

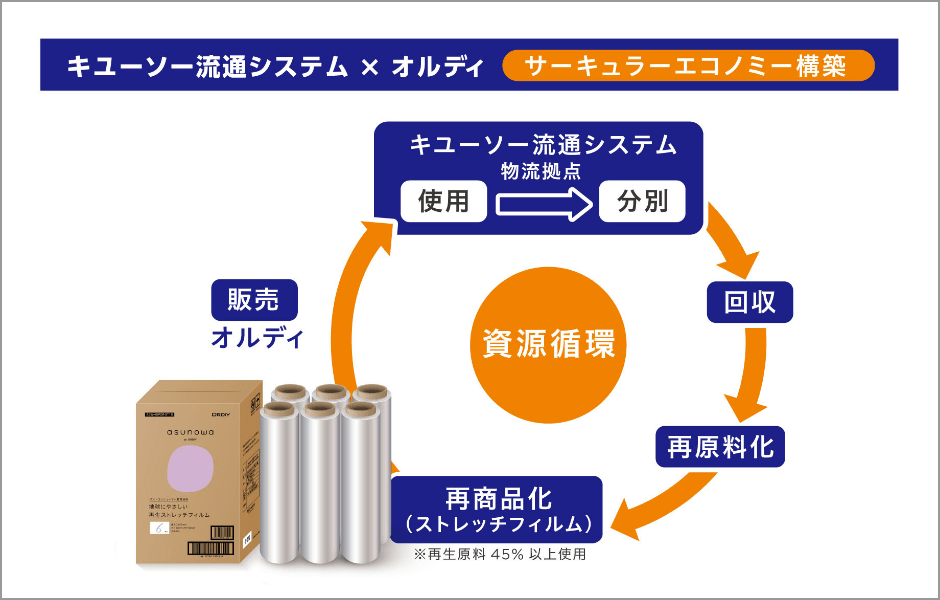

Circular economy of stretch film

Our company and Ordiy Co. Ltd. have established a circular economy by recycling used plastics generated through our business activities and utilizing recycled products.

Specifically, the stretch film used for bundling and securing products and preventing boxes on pallets from collapsing is repurposed as recycled raw material for “Asunowa Recycled Stretch” provided by Ordiy Co., Ltd. By purchasing the recycled product, we actively promote resource circulation.

We are gradually increasing the number of business locations eligible for collection and are working toward nationwide expansion.

Collection of plastic file holders and plastic bottle caps

We participate in the “Askul Resource Recycling Platform (Plastic file holder)” run by Askul Corporation and recycle used plastic file holders.

Previously, these items were disposed of as industrial waste. However, at the Chofu headquarters building, where the initiative began in 2023, 147.15 kg of plastic file holders has been recycled in one year.

Additionally, at Chofu headquarters, we donate plastic bottle caps to the NPO Cap Piggy Bank Promotion Network. The organization donates the proceeds from the sale of collected plastic bottle caps to agencies that provide vaccines to developing countries. In 2023, we contributed 57.8 kg of plastic bottle caps, helping to cover the vaccine costs for approximately 28 people.

Even in the future, we will continue to promote resource circulation while striving to reduce usage.

Collected plastic file holders

Collected plastic file holders