Sustainability

SustainabilityRealization of a Safe and Secure Society

As a leading company in food logistics, which is responsible for social infrastructure, we take necessary measures to ensure safe operations, adhering to the principle “safety takes precedence over everything”. We also comply with our Group’s proprietary know-how and strictly formalized management standards to provide enhanced and stable logistics quality. Our company ensures that the items entrusted to us are delivered to the promised location in the same condition and quality as when they were received.

Transportation Safety Management

Below are the details of the initiatives implemented by K. Tis Corporation, which serves as the Group’s main transportation arm.

>> K. Tis Corporation Transportation Safety Management

Scene from National Transportation

Scene from National TransportationSafety Skill Competition

Promotion of Occupational Safety and Health

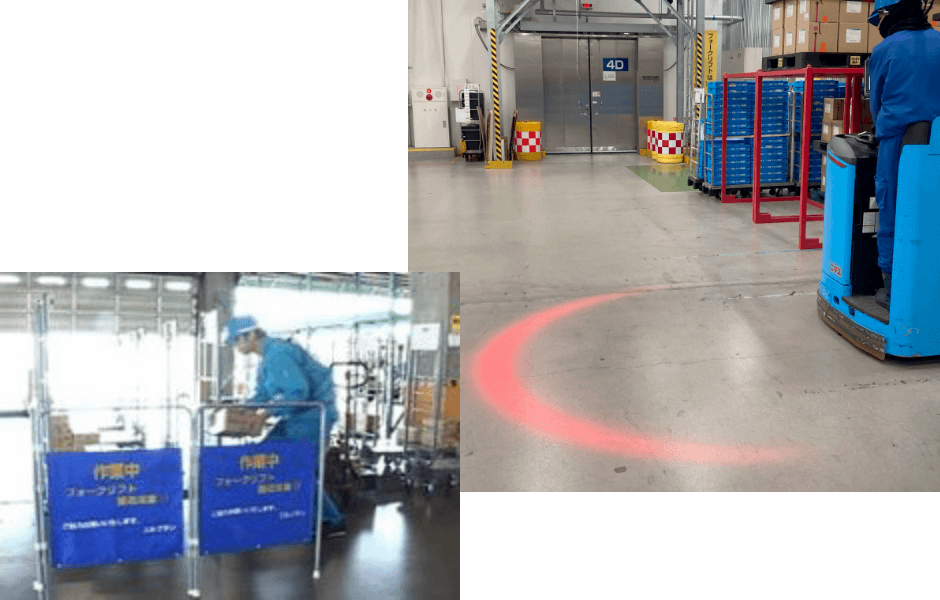

Measures to prevent accidents between workers and forklifts during warehouse operations

We are taking various measures to ensure the safety of employees during warehouse operations.

As an example, to prevent contact between employees working inside the warehouse and forklifts, we have created dedicated partitions to encourage caution and ensure a safe working space.

Additionally, line lights have been fitted to the bodies of forklifts that indicate the direction of travel and vehicle width so that an approaching forklift can be detected even in places where the noise is loud or where there are blind spots. Various measures are taken to prevent accidents.

Collision Prevention Measures for Forklifts

Collision Prevention Measures for ForkliftsHealth management (medical checkups, stress checks)

Regular health checkups and stress checks are conducted as required by law, and interviews are conducted and recommended as necessary.

Additional health management measures have been implemented to enable employees to continue working in good health by subsidizing the costs of supplementary checkups for lifestyle-related disease prevention, cancer screenings, and influenza vaccinations for employees and their dependents.

At our Chofu headquarters, instructors are regularly invited for CPR training sessions to ensure that anyone can respond appropriately in the event of a medical emergency.

First aid training

First aid trainingImplementation of occupational safety and health measures

(safety measures for facilities and machines)

To ensure that work in the warehouse is carried out safely, we have entered into maintenance contracts with material-handling equipment manufacturers and group companies employing qualified mechanics for automated warehouses, material-handling machinery installed in warehouses, and forklifts used as transportation equipment. We conduct monthly and annual voluntary and statutory inspections.

Every month, we create posters summarizing key points to prevent accidents and strive for safety education.

Inspection work

Inspection workLogistics Quality Management

KRSG quality standard

In our core business, we operate in compliance with the KRSG Quality Standard, a standard operating manual for order processing, transportation, and cargo handling, to prevent issues such as administrative errors related to orders, transportation problems (wrong delivery and temperature control errors etc.), and warehouse operation issues (product damage and picking mistakes etc.). Our compliance is achieved through collaboration between K. Tis Corporation, which handles transportation functions, K. LP Corporation, which manages in-warehouse cargo handling functions, and our company, which oversees the coordination of orders for both companies.

In addition, our Group places great importance on the quality of our personnel and the six core qualities.

- Human resources quality:

- The quality of developing talented individuals who possess the abilities to “Take Initiative”, “Think Critically”, and “Work in Teams”, and who are educated and trained in the knowledge and know-how required for business operations, demonstrating their skills honed both within and outside the company

- Product quality:

- The standard at which products can be delivered to customers without compromising their functional quality during transportation, delivery, or shipping

- Work quality:

- The error-free standard for operations and delivery

- Delivery quality:

- The standard for accurately adhering to promised delivery dates, with no delays or shortages

- Safety quality:

- The standard of achieving no traffic accidents, occupational disasters, work-related accidents, or system troubles within the center

- Impression quality:

- The standard of giving a positive impression through the use of courteous language and a pleasant attitude

- Environmental quality:

- The standard of environmental contribution, such as exhaust gas reduction, energy conservation, and waste reduction

Internal audits and follow-up systems for major businesses

In our major business operations, the quality audit department conducts annual on-site audits to ensure that operations comply with the KRSG Quality Standard, the standard operating manual.

In the unlikely event of a serious accident, we conduct surprise inspections to ensure that measures to verify whether recurrence prevention measures are implemented continuously and conduct audits to ensure recurrence prevention.

We will continue to promote quality management to ensure the provision of safe and reliable logistics quality.